Industries are always searching for ways to improve products before putting them out on the market. They need unconventional design solutions to meet a complex and competitive business environment and subsequently realize the potential of their product right from its conceptualization to make informed decisions across the entire value chain.

Their objective includes eradicating reworks, dropping the need for costly prototypes and decreasing development costs. Technology such as Computational Fluid Dynamics (CFD) proposes the solution to address these design challenges.

HOW DOES CFD SIMULATION SERVICE HELP?

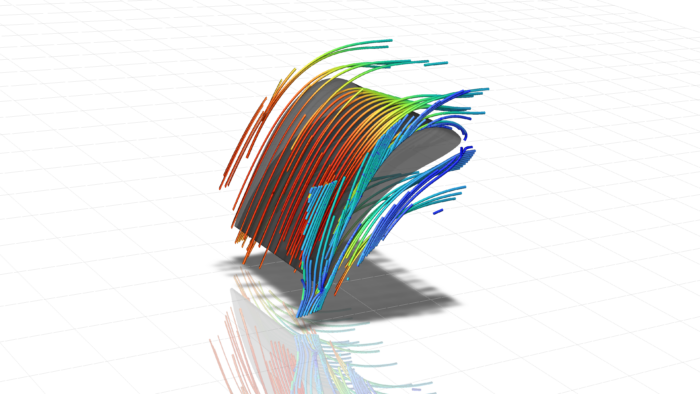

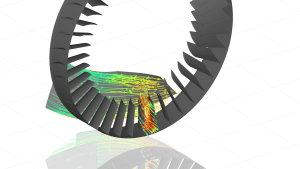

CFD helps to comprehend flow behaviours in equipment and optimize flow patterns, flow rates; pressure drops, etc. CFD software analyses heat-transfer designs and fluid flow, permitting engineers to determine how a design will execute under real-world conditions. Moreover, it can highlight the opportunities for optimization ahead of time, thereby eliminating the risks and ditching costly warranty problems.

EFFICIENCY, FIDELITY AND FLEXIBILITY

NSI has been providing noteworthy value to customers using advanced Computational Fluid Dynamics (CFD) modelling techniques in cracking complex flow-related problems. It is valuable and beneficial when design correlations are not available; however, it can also be used effectually to remove conservatism associated with the existing design correlations. Cost savings can be great when CFD is added to Fitness-For-Service analyses or new component designs.

Our CFD designs serve as an essential link for design engineers and manufacturing organizations to help realize their product promise right from concept to realization. Having successfully completed the complex and critical projects, our CFD engineers deliver solutions to major engineering verticals globally.

UNRAVELING COMPLEX PHYSICS

NSI experienced analysts are capable of modeling fluid flow problems that involve complex physical phenomena including:

TRANSIENT FLOW

TURBULENCE MODELING

COMPRESSIBLE FLOW

MULTIPHASE FLOW

BUOYANCY DRIVEN NATURAL CONVECTION

RADIATION HEAT TRANSFER

CONJUGATE HEAT TRANSFER

MULTISPECIES AND CHEMICAL REACTIONS

PHASE CHANGE

FLUID STRUCTURE INTERACTION (FSI)

At NSI, we board a team of CFD engineers, mechanical engineers, industry experts and CAD professionals who work together to deliver solutions to our clients and create more value for their end customers.

Our engineering facility has state-of-the-art hardware and professional CFD solvers, talented enough to handle large and complex geometries. You can completely rely on our simulation team to give you deep insight into the issues affecting your product development and quality control procedures.